How to build sustainable housing? This question is addressed in an article that recently appeared in the online magazine luxurydefined by Christie’s International Real Estate. According to them new technologies will provide better housing, faster, more affordably, and more sustainably: 3D-printed architecture could kickstart a revolution in the construction industry.

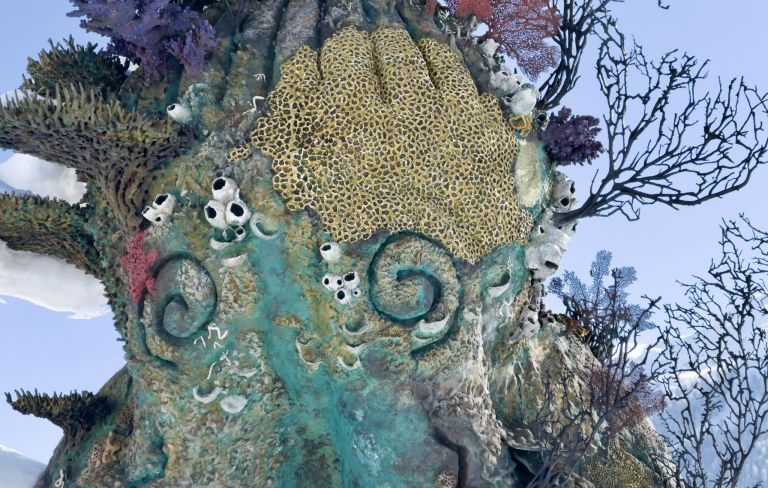

Circular house Tecla was built from clay using Wasp’s Crane 3D printer. It maximizes the performance of a material that is both one of the oldest and one of the most stimulating for the future of the green economy: raw earth.

According to a report by Grand View Research the global 3D construction market is set to grow by an incredible 91 percent between now and 2028. Champions of the revolutionary building practice believe that 3D-printed architecture could provide affordable housing that is more environmentally friendly than its bricks-and-mortar counterparts, and could also be used to provide shelter that is quick to assemble in disaster-hit regions.

America’s first 3D-printed homes, located in Texas, have been sold. Sustainably built using Icon’s proprietary 3D-printing technology and advanced materials, these homes are designed to last longer than traditional materials.

“3D-printed architecture is a paradigm shift. This transformation allows us to improve construction processes, making them more sustainable,” says Massimo Moretti, founder of WASP (World’s Advanced Saving Project). He founded his company with the aim of developing a 3D printer that can print houses in a totally eco-friendly way, addressing some of the housing problems that currently face, or will face, the world in the near future.

You can read the full article by luxurydefined with many examples and richly illustrated online here.

You can also read more about 3D printing in architecture on archdaily.com under the title: “Can 3D Printing Reshape Residential Architecture as We Know it”.